The biggest issue in 3D printing is…

As you know, my 3D printing based developments put my printers (an Ender3 and a Sunlu S9+) to a lot of stress. When I’m working on a new project (all the time in fact), it’s not uncommon to have both printers working 24 hours a day. Some prints take more than two days!

Perfect to put the equipment to (very) hard test!

But during these prints, the part that suffers the most is by far the hotend: the set made up of the heating block (to melt the PLA), the nozzle, the heat sink, the ptfe tube (the tube that goes from the extruder to the heating block) and the heat breaker.

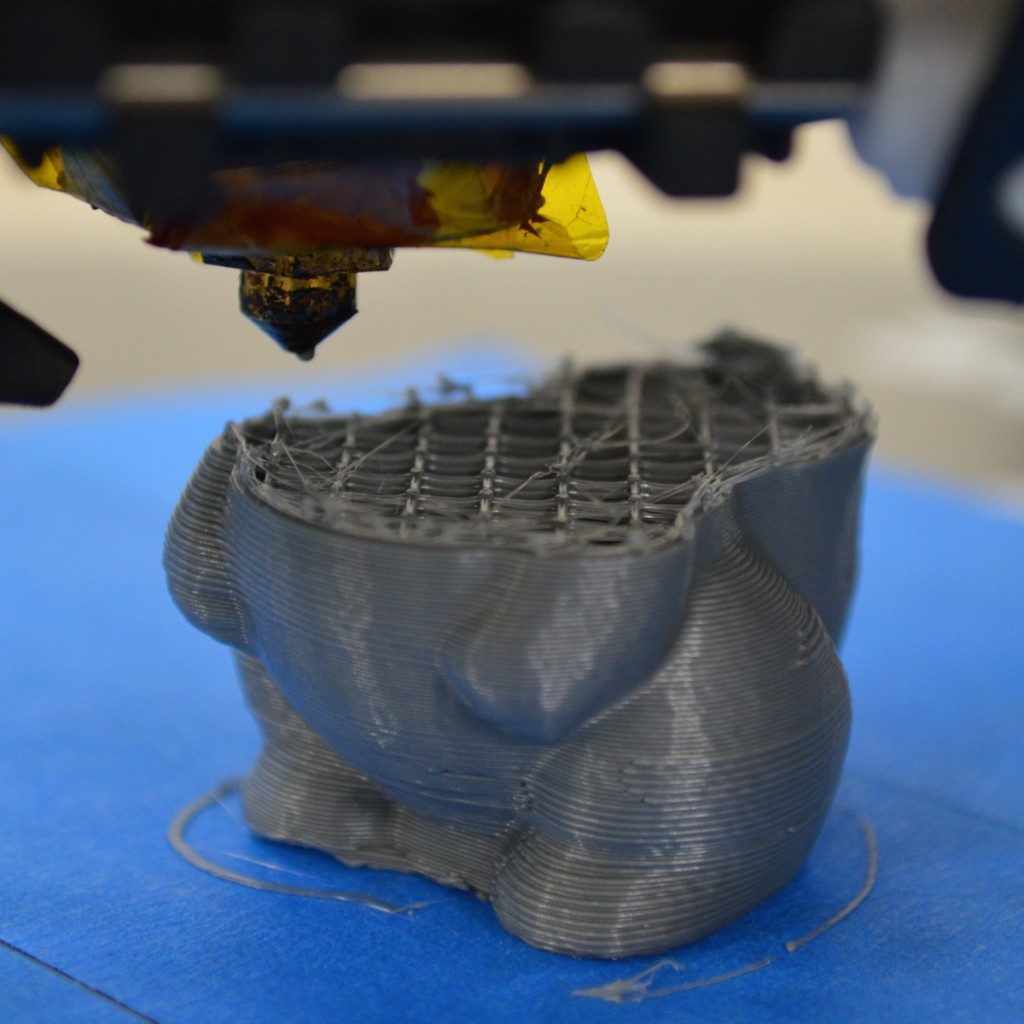

In the printing problems encountered, it is most often here that the problem is located: with the heating and the melted plastic, the components can tend to expand, gaps appear and finally the plastic encounters difficulties to join the output: it is what is called clogging:

The heart of the problem is the deformation of the PTFE (or bowden tube): it is the most temperature sensitive material, and it is in direct contact with the nozzle in the heating block. I also recommend using Capricorn tube to reduce the risk of problems.

The definitive solution is :

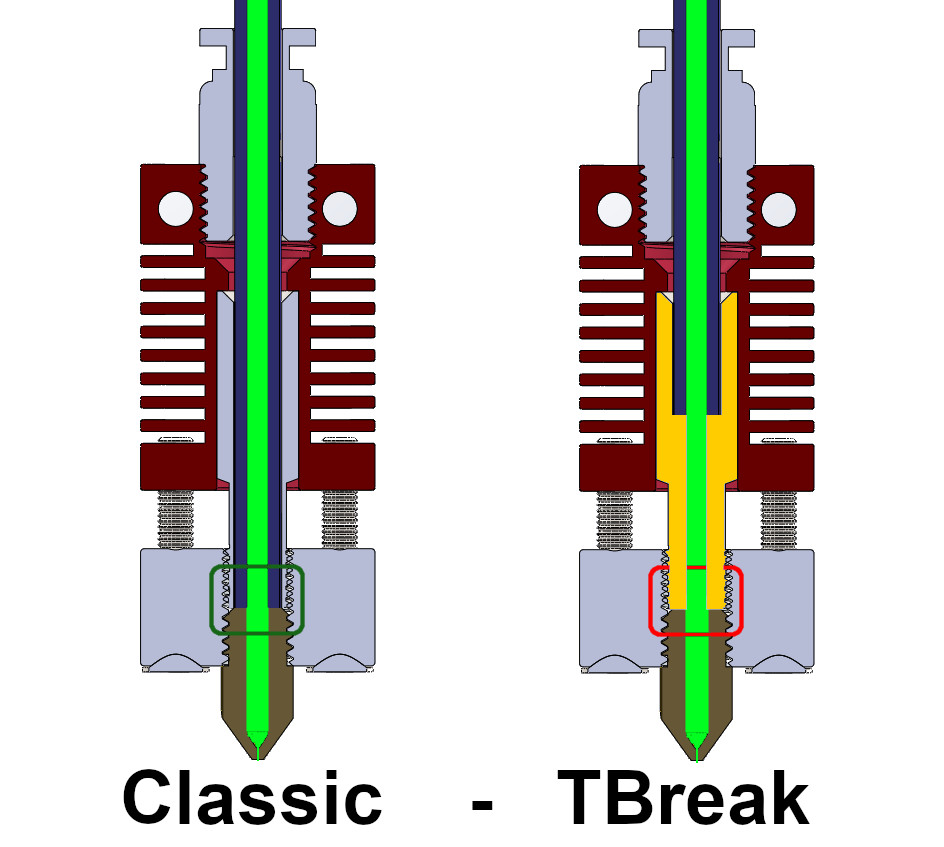

But apparently, there is a “simple” solution to this problem: rather than having the ptfe come in contact with the nozzle (and thus deform, clog etc etc), you can use the CR10 T-Crazy heat break from Mellow Store. Why ? because The PTFE stops in the heat sink, and it is the heat break that finishes guiding the PLA to the nozzle. This way, the PTFE tube is not subjected to significant temperature variations. In addition, the nozzle is mechanically sealed against the heat break (and not against the PTFE), which ensures that the PLA cannot get lodged between the two.

This is a solution I’ve been using for a few months now on the Sunlu and I’m very satisfied with it: I disassembled the whole thing for the first time yesterday, and it looked like it had just been assembled: no residue, no trace of heating. Moreover, it can be installed on popular machines (Ender 3, CR10 etc) without having to change the heating block and therefore without having to adapt the wiring.

You may ask me why this solution is not more widespread: probably because it requires an exemplary quality of manufacturing: It takes an extraordinary precision to make the metal tube as smooth as the PTFE tube and not interfere with the sliding of the plastic wire. The Mellow Store product is made of two components: copper for the part placed in the heatsink, and titanium for the part that screws into the heating block.

Find the TBreak heat break on the Mellow Store.

And don’t forget your 10% discount at checkout on the Sunlu website via this link!