What means 3D printing ?

3D printing consists of using a printer to create 3D objects.

The printer.

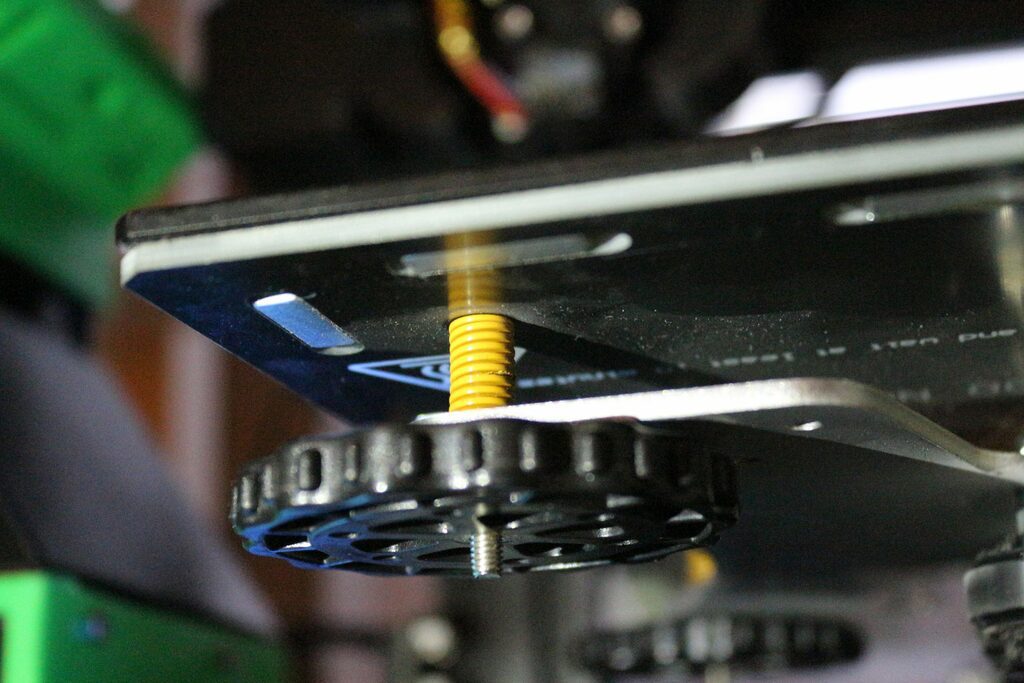

Let’s start with the printer. Multiple technologies exist, but at our level, we will use FDM printers (Fused Deposition Modeling): we deposit layers of molten plastic. The plastic is melted by a mobile head which layer after layer makes our 3D model “appear”. See our guide for the most popular models.

The plastic.

The plastic? Mostly PLA (although ABS and PETG are quite common). It’s easy to work with and very affordable: about 20€/kg. To give you an idea, the SRT box, which is a very substantial project, requires about 1.3kg of plastic, or about 26€. See our guide to different PLAs.

The 3D files.

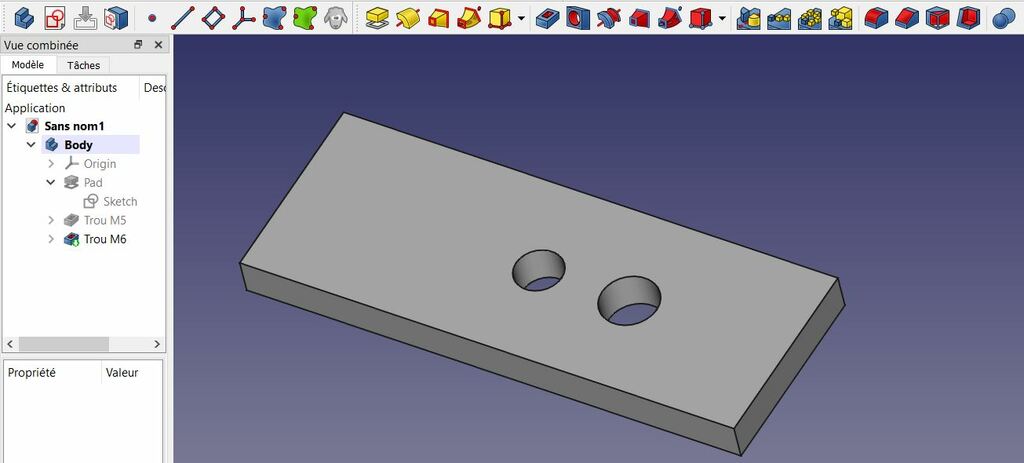

You can design 3D files to print yourself, using software like Freecad (free), SolidWords, Fusion360. It is a long learning process. However with time you will be able to draw more and more complex parts, faster and faster. For the record, I started 3D drafting with this simple engineering advice, “draw your parts as you would have machined them.”

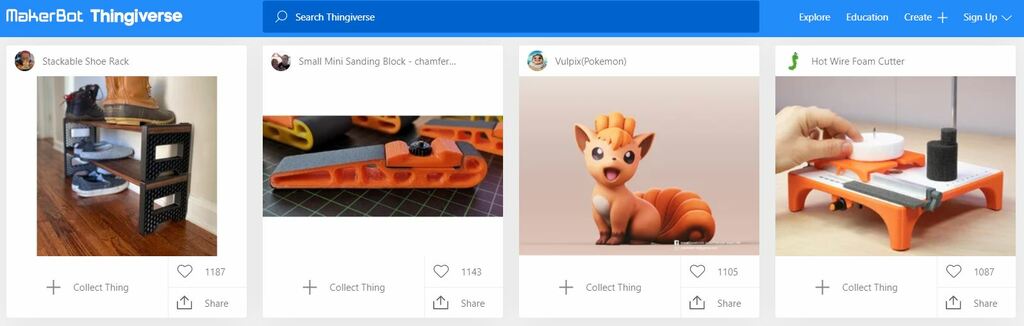

You can also directly download files to print (the 3D equivalent of .pdf). The most common formats are .stl or .obj, on sites like Thingiverse, Cults3D…Some files are free, others are not. In my experience, you will always find a free project for what you are looking for. STL is not an editable format, you will have a lot of trouble to modify the dimensions.

The Slicer: the software that sends 3D files to the printer!

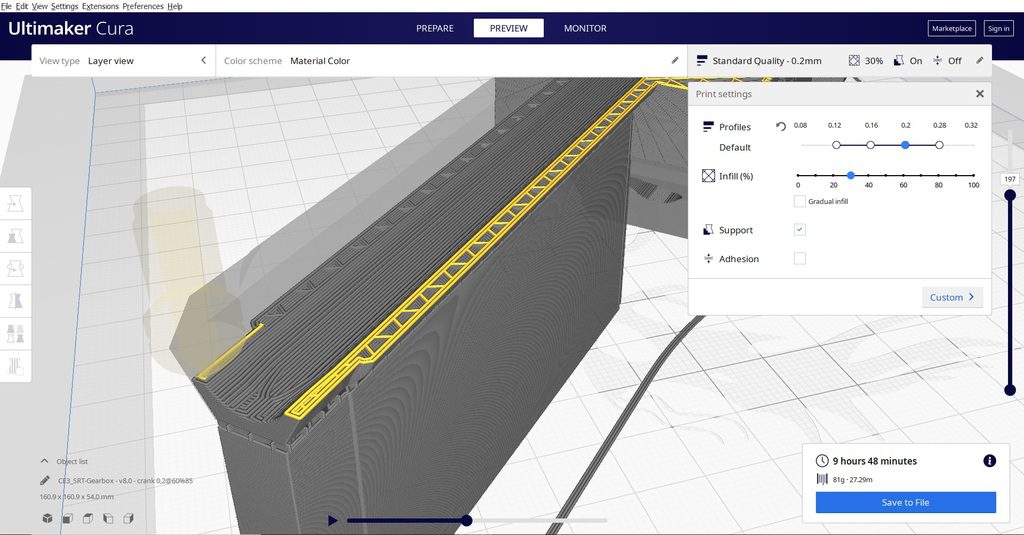

Once you have your file, you need to use a “slicer”, which is the software that will allow you to convert the 3D file specifically for your printer (a bit like the driver of a 3D printer). I recommend using Cura. In particular, we will determine the printing direction (which side will be in contact with the printer’s plate) and what the fill rate will be. Indeed, most printed parts will be almost hollow, which makes 3D printing particularly economical.

The file is then transferred from the slicer to the 3D printer (by cable, SD card, wifi, etc.), and off you go. 3D printers often require adjustments and maintenance. For example, you need to make sure that the platen is perfectly flat in relation to the nozzle.

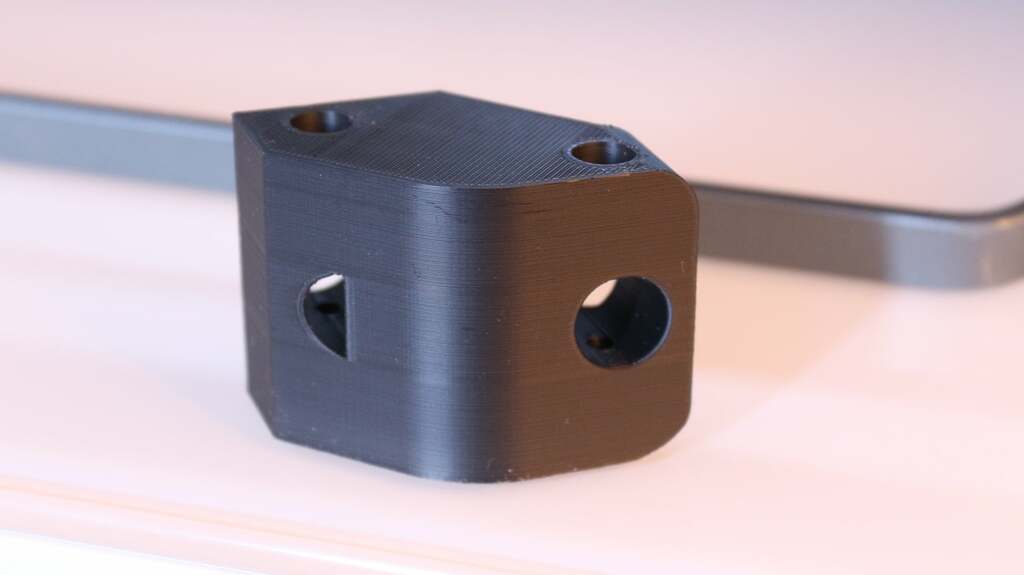

We finally have our 3D object that “appears” in front of our eyes!